Whirlpool Duet dryer error codes

These error code explanations can help you diagnose a problem with your Whirlpool Duet HE dryer. For repair how-to help, visit the PartsDirect repair help section, which includes repair help for dryers, other major appliances, lawn and garden equipment, garage door openers, vacuum cleaners and more. Search for your model number to find a complete list of replacement parts for your dryer.

Power failure

A power failure occurred while the dryer was running. Press Start to continue the cycle or Stop to clear the display. If frequent power failures occur, check the outlet cord for the dryer.

Main electronic control board failure

Unplug the dryer for 5 minutes and then plug it in. If the code returns, replace the main electronic control board.

Keypad/User Interface failure

A button is stuck on the keypad on one of the two user interface control assemblies in the console. If you can't free the button, replace the user interface control assembly with the stuck button.

Outlet thermistor failure

The control detects an electrically open outlet thermistor (temperature sensor). Unplug the dryer and check the resistance of that thermistor, which should be about 10,000 ohms. If the outlet thermistor is defective, replace it.

Outlet thermistor failure

The control detects an electrically shorted outlet thermistor (temperature sensor). Unplug the dryer and check the resistance of that thermistor, which should be about 10,000 ohms. If the outlet thermistor is defective, replace it.

Inlet thermistor failure

The control detects an electrically open inlet thermistor (temperature sensor). Unplug the dryer and check the resistance of that thermistor, which should be about 50,000 ohms. If the inlet thermistor is defective, replace it. NOTE: The inlet thermistor is combined with the high-limit thermostat on this dryer.

Inlet thermistor failure

The control detects an electrically shorted inlet thermistor (temperature sensor). Unplug the dryer and check the resistance of that thermistor, which should be about 50,000 ohms. If the inlet thermistor is defective, replace it. NOTE: The inlet thermistor is combined with the high-limit thermostat on this dryer.

Moisture sensor failure

Unplug the dryer and check the wiring connections on the moisture sensor. If the wiring connections are sound, replace the moisture sensor.

Moisture sensor failure

Unplug the dryer and check the wiring connections on the moisture sensor. If the wiring connections are sound, replace the moisture sensor.

Restricted airflow

Clean lint from the lint screen. If you use fabric softener sheets, wash the lint screen with water and a soft- bristled brush to remove fabric softener buildup. Clear any clog or restriction from the exhaust air duct system to the outside of your home.

No communication between the electronic control board and the user interface control board assemblies

Unplug the dryer. Check the wire harness connections between the main electronic control board and the user interface control board assemblies. If the connections are sound, have a technician diagnose the cause of the communication failure. The main electronic control board and/or the user interface control assemblies might need to be replaced.

User interface control assembly failure

Unplug the dryer. Check the wire harness connections between the user interface assemblies. Also check the wire harness connections between the main electronic control board and the user interface assemblies. If the wiring connections are sound, then one or both of the user interface control assemblies probably needs to be replaced.

Most common symptoms to help you fix your dryers

Choose a symptom to see related dryer repairs.

Main causes: bad gas valve coils, broken heating element, tripped safety thermostat or fuse, bad operating thermostat, c…

Main causes: bad drum support roller, damaged idler pulley, broken blower fan blade, worn drum glide bearing, bad drive …

Main causes: damaged door strike, worn door catch…

Main causes: clogged exhaust vent, bad motor relay, loose dryer door catch, bad door switch, control system failure, fau…

Main causes: door switch failure, lack of power, broken belt, blown thermal fuse, bad drive motor, control system failur…

Main causes: clogged exhaust system, heating system failure, deposits on moisture sensor, control system failure…

Main causes: bad timer or electronic control board, door switch failure…

Main causes: lack of electrical power, bad power cord, wiring failure, bad control board, blown thermal fuse, bad door s…

Most common repair guides to help fix your dryers

These step-by-step repair guides will help you safely fix what’s broken on your dryer.

How to replace an electronic control board in an electric dryer

The electronic control board manages the components and controls the cycle times in your electric dryer. Follow these st…

How to replace a heating element in an electric dryer

The heating element in an electric dryer generates the dryer's heat—it's one of the first things to check if the air in …

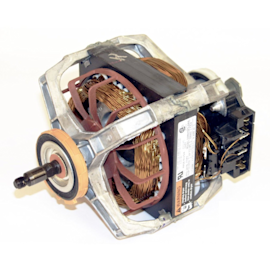

How to replace a dryer drive motor

A defective drive motor struggles to rotate the drum or might not turn the drum at all. Follow the steps in this dryer r…

Effective articles & videos to help repair your dryers

Use the advice and tips in these articles and videos to get the most out of your dryer.

Get expert tips on using your dryer efficiently to save energy.…

Learn about all the convenient features on our Sears PartsDirect website that make your parts purchases easier.…

Get answers to frequently asked questions about Sears and Sears PartsDirect.…