Frigidaire laundry center washer error codes

These error code explanations help troubleshoot a problem with your Frigidaire laundry center washer. Models FFLE3911, FFLG3911, FFLE4033 and FFLG4033 display these codes.

When your Frigidaire laundry center washer quits working, enter the diagnostic test mode to hear error code beeps or see error code numbers that will likely point you in the direction of the failure. The Frigidaire stackable washer/dryer has separate diagnostic test modes for the washer and dryer, so you'll need to enter the diagnostic test model for the portion of the laundry center that stops working. This article tells you how to enter the laundry center washer diagnostic test mode and display error codes. A Frigidaire stackable washer/dryer without a digital display beeps to signal error codes. Use the chart below to determine the error code signaled by Frigidaire laundry center beeps. A Frigidaire laundry centers with a digital display shows the error code numbers in the display.

Once you know the error code your laundry center washer is signaling, troubleshoot the problem using the chart below.

If the dryer on your laundry center has stopped working, find out how to enter the dryer's diagnostic mode and troubleshoot error codes.

For repair how-to help, visit the PartsDirect repair help section, which includes repair help for refrigerators, other major appliances, lawn and garden equipment, garage door openers, vacuum cleaners and more. Search for your model number to find a complete list of replacement parts for your laundry center.

Fill time too long

Make sure that the water supply faucets behind the laundry center are fully open. Check for frozen fill lines in the winter. Unplug the laundry center and disconnect the fill hoses from the back of the washer. Check for proper water flow through the fill hoses. If water flow is inadequate, have a plumber repair the water supply to the faucets. If water flows okay, check the inlet screens on the water valve assembly. If you find clogged screens, replace the water valve assembly rather than cleaning the screens. Cleaning could allow debris to enter the valves, resulting in the valves sticking open and causing a flood. Check the drain hose for proper installation. An improperly installed drain hose causes fill water to siphon out through the washer drain. If you find no problems with the above issues, you'll likely need to replace the water valve assembly.

Water leak in the tub or air leak in the water level pressure sensor air hose

Check the drain hose for proper installation. An improperly installed drain hose causes fill water to siphon out through the washer drain. Manually drain the water out of the washer. Unplug the laundry center and check the washer outer tub for cracks or leaks such as water dripping from the bottom of the washer tub or a hose. Replace the tub if it leaks. If you don't find any water leaks, check the water level sensor air hose for air leaks. Replace the air hose if it leaks. If the hose doesn't leak, replace the water level sensor because it's not detecting the water level in the washer.

Drains slowly

Check your house's washer drain and the washer's drain hose for clogs and clear any clogs found. Unplug the laundry center, manually drain the washer and check the drain pump for and clear any clogs. If the drain path is clear, you'll likely need to replace the drain pump.

Water level sensor is faulty

Unplug the laundry center and check the wire harness connections between the water level sensor and the washer electronic control board. Reconnect any loose wires and repair any broken wires. If the wire harness connections are okay, replace the water level sensor. If the problem continues, replace the washer electronic control board.

Unstable water level sensor reading when draining

If water drains slowly or not at all, check your house's washer drain and the washer's drain hose for clogs. Clear any clogs. Unplug the laundry center, manually drain the washer and check the drain pump for a clog. If the drain path is clear, you'll likely need to replace the drain pump. If the washer drains properly, check the water level sensor air hose for air leaks. Replace the air hose if it leaks. If the hose doesn't leak, replace the water level sensor because it's not detecting the water level in the washer. If the problem continues, replace the washer electronic control board because it isn't detecting water level sensor signals properly.

Water level sensor detects overfill

If the washer overfilled, unplug the power cord and see if water continues to fill the tub. If so, replace the water valve assembly because a water valve isn't closing. If the washer didn't overfill, you'll likely need to replace the water level sensor because it isn't accurately detecting water level.

Lid opened or lid won't lock

Unplug the laundry center and check the wire harness connections between the washer lid lock and the washer electronic control board. Reconnect any loose wires and repair any broken wires. If the wire harness connections are okay, replace the lid lock. If the problem continues, replace the washer electronic control board.

Lid won't unlock

Unplug the laundry center and check the wire harness connections between the washer lid lock and the washer electronic control board. Reconnect any loose wires and repair any broken wires. If the wire harness connections are okay, replace the lid lock. If the problem continues, replace the washer electronic control board.

Lid lock defective

Unplug the laundry center and check the wire harness connections between the washer lid lock and the washer electronic control board. Reconnect any loose wires and repair any broken wires. If the wire harness connections are okay, replace the lid lock. If the problem continues, replace the washer electronic control board.

Lid lock communication failure

Unplug the laundry center and check the wire harness connections between the washer lid lock and the washer electronic control board. Reconnect any loose wires and repair any broken wires. If the wire harness connections are okay, replace the lid lock. If the problem continues, replace the washer electronic control board.

Lid lock input failure

Unplug the laundry center and check the wire harness connections between the washer lid lock and the washer electronic control board. Reconnect any loose wires and repair any broken wires. If the wire harness connections are okay, replace the lid lock. If the problem continues, replace the washer electronic control board.

Drive motor under speed

Check for overloading. Load capacity is about 20 pounds. Remove some items if you find the basket overloaded. Check for water in the tub. If you find water, check for excessive suds. The drain pump can't remove the water before the spin cycle if the water is too sudsy. If you don't find excessive suds, check your house's washer drain and the washer's drain hose for clogs and clear any clogs found. Unplug the laundry center, manually drain the washer and check the drain pump for a clog. If the drain path is clear, you'll likely need to replace the drain pump. If you didn't find water in the tub, pull out the clothes and manually spin the tub to see if it rotates smoothly. If not, then the motor and gear case could have failed or an obstruction in the drive system could be the problem. Unplug the laundry center and remove the agitator. Pull out the spin basket and check for obstructions between the spin basket and the outer tub. If you find no obstructions, replace the motor and gear case.

High current on the drive motor

Check for overloading. Load capacity is about 20 pounds. Check for excessive suds in the tub. The drain pump can't remove the water before the spin cycle if the water is too sudsy. The remaining water can cause motor drag resulting in high motor current draw. If you find excessive suds, remove the clothes, bail out the sudsy water and then rewash the load. If you didn't find excessive suds, unplug the laundry center. Remove the front washer panel and check the wire harness connections between the motor control board and motor and gear case. Reconnect any loose wires or replace the wire harness if damaged. If the wire harness is okay, manually spin the tub to see if it rotates smoothly. If not, then the motor and gear case could be broken or an obstruction in the drive system could be the problem. Unplug the laundry center and remove the agitator. Pull out the spin basket and check for obstructions between the spin basket and the outer tub. If you find no obstructions, check the resistance of the motor windings-you should measure between 6 and 8 ohms on each motor winding. If you don't measure resistance within that range on each motor winding, replace the motor and gear case. If motor winding resistance is okay, replace the motor control board.

No tachometer signal for 3 seconds

Check for overloading. Load capacity is about 20 pounds. Pull out some of the load and restart the cycle. If you didn't overload the washer, unplug the laundry center and remove the front washer panel. Check the wire harness connections between the motor control board and the motor and gear case. Reconnect any loose wires or replace the wire harness if damaged. If the wire harness is okay, manually spin the tub to see if it rotates smoothly. If not, then the motor and gear case could have failed or an obstruction in the drive system could be the problem. Remove the load. Pull off the agitator then pull out the spin basket and check for obstructions between the spin basket and the outer tub. If you find no obstructions, check the resistance of the motor windings-you should measure between 6 and 8 ohms on each motor winding. If you don't measure resistance within that range on each motor winding, replace the motor and gear case. If motor winding resistance is okay, replace the motor control board.

Motor control board is overheated

Check for overloading. Load capacity is about 20 pounds. Pull out some of the load and restart the cycle. If you didn't overload the washer, unplug the laundry center. Remove the front washer panel and check the wire harness connections between the motor control board and motor and gear case. Reconnect any loose wires or replace the wire harness if damaged. Check the resistance of the motor windings u2013 you should measure between 6 and 8 ohms on each motor winding. If you don't measure resistance within that range on each motor winding, replace the motor and gear case. If motor winding resistance is okay, replace the motor control board.

High voltage at the motor control board

High power supply voltage caused by power surges during an electrical storm can cause this code. Contact your local electrical supplier to correct voltage supply problems. If the power supply voltage is okay, If the wiring connections are okay, replace the motor control board. If the problem continues, replace the washer electronic control board.

Communication error between the motor control board and washer electronic control board

Unplug the laundry center and check the wire harness connection between the motor control board and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. If the wiring connections are okay, replace the motor control board. If the problem continues, replace the washer electronic control board.

Communication error between the user interface board, motor control board and washer electronic control board

Unplug the laundry center and check the wire harness connections between the user interface board and the washer electronic control board. Also check the wire harness connections between the motor control board and the washer electronic control board. Reconnect any loose wires or replace any damaged wire harnesses. If the wiring connections are okay, replace the user interface board. If the problem continues, replace the motor control board. If the problem still continues, replace the washer electronic control board.

Motor control board failure

Unplug the laundry center and check the wire harness connection between the motor control board and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. If the wiring connections are okay, replace the motor control board. If the problem continues, replace the washer electronic control board.

Low voltage at the motor control board

Low power supply voltage caused by brownouts or power surges during an electrical storm can cause this code. Contact your local electrical supplier to correct voltage supply problems. If the power supply voltage is okay, unplug the laundry center and check the wire harness connection between the motor control board and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. If the wiring connections are okay, replace the motor control board. If the problem continues, replace the washer electronic control board.

Washer temperature sensor failure

Unplug the laundry center and check the wire harness connections between the washer temperature sensor and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. Check the resistance of the temperature sensor using a multimeter. You should measure between 50,000 ohms and 67,000 ohms at room temperature (72 degrees F). If sensor resistance is out of that range, replace the water valve assembly because the temperature sensor is part of the assembly.

User interface board failure

Unplug the laundry center for 5 minutes to reset the washer electronic control board and user interface board. If the code doesn't clear after restoring power, unplug the laundry center and check the wire harness connections between the user interface board and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. If you find no wiring problems, replace the user interface board.

User interface board communication failure

Unplug the laundry center and check the wire harness connections between the user interface board and the washer electronic control board. Check the wire harness connections between the motor control board and the washer electronic control board. Reconnect any loose wires or replace any wire harness that's damaged. If the wiring connections are okay, replace the user interface board. If the problem continues, replace the motor control board. If the problem still continues, replace the washer electronic control board.

User interface board failure

Unplug the laundry center and check the wire harness connections between the user interface board and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. If the wiring connections are okay, unplug the user interface board from the washer electronic control board and reassemble the washer. Restore power and run the diagnostic test to see if the E92 code appears with the user interface board unplugged. Replace the user interface board if the code doesn't recur. Replace the washer electronic control board if the code appears with the user interface board unplugged.

Washer electronic control board failure

Unplug the laundry center and check the wire harness connections between the user interface board and the washer electronic control board. Check the wire harness connections between the motor control board and the washer electronic control board. Reconnect any loose wires or replace any wire harness that's damaged. If the wiring connections are okay, replace the washer electronic control board.

Washer electronic control board internal memory failure

Unplug the laundry center and check the wire harness connections between the user interface board and the washer electronic control board. Check the wire harness connections between the motor control board and the washer electronic control board. Reconnect any loose wires or replace any wire harness that's damaged. If the wiring connections are okay, replace the washer electronic control board.

Washer electronic control board and user interface board mismatch

Unplug the laundry center and check the wire harness connection between the user interface board and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. If the wiring connections are okay, replace the washer electronic control board.

Washer electronic control board and motor control board mismatch

Unplug the laundry center and check the wire harness connection between the motor control board and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. If the wiring connections are okay, unplug the motor control board wire harness from the washer electronic control board and reassemble the washer. Restore power and run the diagnostic test to see if the E98 code appears with the motor control board unplugged. Replace the motor control board if the code doesn't recur. Replace the washer electronic control board if the code appears with the motor control board unplugged.

User interface board failure

Unplug the laundry center and check the wire harness connection between the user interface board and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. If the wiring connections are okay, replace the user interface board.

Incoming power frequency out of limits

The washer stops and beeps 11 times when incoming power frequency isn't 60 Hz or incoming power voltage isn't correct. You won't be able to start the diagnostic test until you restore incoming power with the right frequency and voltage to the washer. Unplug the washer and have your local electricity provider check the power supply frequency and voltage. If the power supply is okay and the code doesn't clear, replace the electronic control board.

Incoming power voltage too high

The washer stops and beeps 11 times when incoming power frequency isn't 60 Hz or incoming power voltage isn't correct. You won't be able to start the diagnostic test until you restore incoming power with the right frequency and voltage to the washer. Unplug the laundry center and have your local electricity provider check the power supply frequency and voltage. If the power supply is okay and the code doesn't clear, replace the electronic control board.

Incoming power voltage too low

The washer stops and beeps 11 times when incoming power frequency isn't 60 Hz or incoming power voltage isn't correct. You won't be able to start the diagnostic test until you restore incoming power with the right frequency and voltage to the washer. Unplug the laundry center and have your local electricity provider check the power supply frequency and voltage. If the power supply is okay and the code doesn't clear, replace the electronic control board.

Motor control board failure

Unplug the laundry center and check the wire harness connections between the motor control board and the motor and gear case. Reconnect any loose wires or replace the wire harness if damaged. If you find no wiring problems, replace the motor control board. If the problem continues, replace the washer electronic control board.

Washer electronic control board failure

Unplug the laundry center and check the wire harness connections between the washer electronic control board and the motor control board. Reconnect any loose wires or replace the wire harness if damaged. If you find no wiring problems, replace the washer electronic control board.

Washer mode actuator failure

Unplug the laundry center and replace the washer mode actuator if damaged. If you see no damage, check the wire harness connections between the mode actuator and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. If you find no wiring problems, check the resistance of the washer mode actuator using a multimeter. You should measure between 2,800 and 3,100 ohms. Replace the washer mode actuator if resistance is out of that range. Replace the washer electronic control board if mode actuator resistance is okay.

Washer mode actuator sensor failure

Unplug the laundry center and replace the washer mode actuator if damaged. If you see no damage, check the wire harness connections between the mode actuator and the washer electronic control board. Reconnect any loose wires or replace the wire harness if damaged. If you find no wiring problems, check the resistance of the washer mode actuator using a multimeter. You should measure between 2,800 and 3,100 ohms. Replace the washer mode actuator if resistance is out of that range. Replace the washer electronic control board if mode actuator resistance is okay.

Excessive suds detected

The washer electronic control board detected excessive suds during the cycle. The control extends the cycle to remove the excessive suds and then completes the cycle. Use the right amount of high-efficiency (HE) detergent with future loads.

Out of balance

Rebalance the load and restart the washer. If the code appears with a balanced load, unload the washer. Run a cycle with no clothes added. If the code appears with the washer empty, unplug the washer and replace the motor and gear case.

Washer electronic control board failure

Unplug the laundry center and replace the washer electronic control board.

Incoming power frequency out of limits

The washer stops and beeps 17 times when incoming power frequency isn't 60 Hz or incoming power voltage isn't correct. You won't be able to start the diagnostic test until you restore incoming power with the right frequency and voltage to the washer. Unplug the laundry center and have your local electricity provider check the power supply frequency and voltage. If the power supply is okay and the code doesn't clear, replace the electronic control board.

Incoming power voltage too high

The washer stops and beeps 17 times when incoming power frequency isn't 60 Hz or incoming power voltage isn't correct. You won't be able to start the diagnostic test until you restore incoming power with the right frequency and voltage to the washer. Unplug the laundry center and have your local electricity provider check the power supply frequency and voltage. If the power supply is okay and the code doesn't clear, replace the electronic control board.

Incoming power voltage too low

The washer stops and beeps 17 times when incoming power frequency isn't 60 Hz or incoming power voltage isn't correct. You won't be able to start the diagnostic test until you restore incoming power with the right frequency and voltage to the washer. Unplug the laundry center and have your local electricity provider check the power supply frequency and voltage. If the power supply is okay and the code doesn't clear, replace the electronic control board.

Most common symptoms to help you fix your laundry centers

Choose a symptom to see related laundry center repairs.

Main causes: lack of water supply, failed lid switch or lid lock, bad water level pressure switch, control system failur…

Main causes: bad lid switch or lid lock, drive motor failure, broken motor coupler, bad timer, faulty electronic control…

Main causes: blocked exhaust vent, clogged lint screen, bad timer, moisture sensing problems, weak gas valve coils, bad …

Main causes: broken dryer drive belt, weak drive motor, binding drum seals…

Main causes: control system failure, broken heating element, bad gas valve coils, gas supply failure, voltage supply pro…

Main causes: unbalanced load, broken suspension springs or shocks, worn snubber ring…

Main causes: door not fully shut, bad door switch, faulty push-to-start switch, wiring failure, bad drive motor, blown f…

Main causes: clogged drain system, blocked drain hose, bad drain pump…

Main causes: broken lid switch or lid lock, faulty drive motor, drain system problem, broken drive system components…

Most common repair guides to help fix your laundry centers

These step-by-step repair guides will help you safely fix what’s broken on your laundry center.

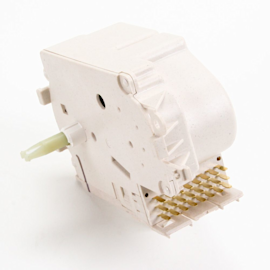

How to replace a laundry center washer timer

If the washer doesn't fill, spin or drain, the timer could be the problem. …

How to replace a laundry center washer snubber ring

If the washer tub bangs the cabinet during the spin cycle even though the load is balanced, you might need to replace th…

How to replace a laundry center dryer door switch

The dryer won’t start if the door switch is defective. Your can replace it in about 15 minutes.…

Effective articles & videos to help repair your laundry centers

Use the advice and tips in these articles and videos to get the most out of your laundry center.

Learn about all the convenient features on our Sears PartsDirect website that make your parts purchases easier.…

Get answers to frequently asked questions about Sears and Sears PartsDirect.…

Learn how to repair broken, frayed or damaged wires in your appliances.…