How to replace the water level pressure switch on a direct-drive top-load washer

This step-by-step washer repair guide shows how to replace the water level pressure switch on a direct-drive top-load washer. The water level pressure switch senses the water level through an air tube attached at the bottom of the tub. As water fills the tub, air pressure in the tube pushes against a diaphragm inside the switch, opening and closing contacts to control the water level and to stop the water once the tub is full. If the water level pressure switch is defective, the washer either won't fill or overfills. Replace the water level pressure switch with a manufacturer-approved washer part.

This repair procedure covers Kenmore, Whirlpool, Maytag, Crosley, Estate and Roper direct-drive, top-load washers.

If you're not sure if your top-load washer has a direct-drive motor, check out our washer FAQs to see how you can tell.

This video explains how to replace the water level pressure switch in a direct-drive top-load washer.

Instructions

- 01.

Shut off the electricity

Unplug the power cord from the wall outlet.

Wear work gloves to protect your hands.

- 02.

Remove the water level control knob

Pull the water level control knob off the stem of the water level pressure switch.

PHOTO: Pull the water level control knob off the stem.

- 03.

Open the control console

Pull the plastic end caps off the sides of the control console.

Remove the screws at the base of the control console.

Pull the control console slightly forward and then swing it over the top of the back panel.

Tip: Some models have the screws on the back of the end caps instead of on the front of the control console. Other models have spring clips under the end caps instead of screws. Remove the rear screws or use a putty knife to release the spring clips.

PHOTO: Remove the plastic endcaps from the control console.

PHOTO: Remove the screws at the base of the control panel console.

PHOTO: Flip the console up and back.

- 04.

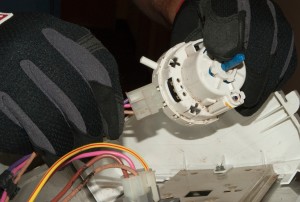

Remove the water level pressure switch

Disconnect the air hose from the water level pressure switch.

Press the locking tab to release the pressure switch and rotate the switch 1/8 turn counterclockwise to release it from the console panel.

Disconnect the wire harness from the pressure switch and pull the switch out of the console.

PHOTO: Disconnect the air hose from the water level pressure switch.

PHOTO: Release the pressure switch from the control panel.

PHOTO: Disconnect the wire harness from the pressure switch.

- 05.

Install the new water level pressure switch

Connect the wire harness to the new water level pressure switch.

Position the new pressure switch on the console panel with the air hose connection in the 3 o'clock position.

Push the pressure switch into the console panel and rotate the pressure switch 1/8 of a turn clockwise to engage the locking tab.

Connect the air hose to the new water level pressure switch.

PHOTO: Install the new pressure switch.

PHOTO: Connect the air hose to the new water level pressure switch.

- 06.

Reinstall the control console

Position the control console on the top panel of the washer.

Reinstall the mounting screws at the base of the control console.

Snap the plastic end caps onto the sides of the control console.

PHOTO: Close the console.

PHOTO: Reinstall the control console screws.

PHOTO: Reinstall the plastic endcaps.

- 07.

Reinstall the water level control knob

Line up the flat side of the control knob with the flat side of the shaft on the new water level pressure switch.

Push the water level control knob down onto the water level pressure switch shaft.

PHOTO: Reinstall the water level control knob.

- 08.

Restore the power

Plug the washer into the electrical outlet.

Most common symptoms to help you fix your washers

Choose a symptom to see related washer repairs.

Main causes: clogged drain hose, house drain clogged, bad drain pump, water-level pressure switch failure, bad control b…

Main causes: worn agitator dogs, bad clutch, broken motor coupler, shifter assembly failure, broken door lock, suspensio…

Main causes: bad lid switch or door lock, bad timer or electronic control board, wiring failure, bad water inlet valve a…

Main causes: broken lid switch or lid lock, bad pressure switch, broken shifter assembly, faulty control system…

Main causes: unbalanced load, loose spanner nut, worn drive block, broken shock absorber or suspension spring, debris in…

Main causes: no water supply, bad water valves, water-level pressure switch failure, control system failure, bad door lo…

Main causes: lack of electrical power, wiring failure, bad power cord, electronic control board failure, bad user interf…

Main causes: leaky water inlet valve, faulty water-level pressure switch, bad electronic control board…

Main causes: water heater failure, bad water temperature switch, faulty control board, bad water valve, faulty water tem…

Repair guides for top-load washers

How to replace the shifter assembly in a top-load washer

The shifter motor switches the washer's drive motor between the agitate and spin modes. If your washer's basket won't bu…

How to replace the electronic control board on a top-load washer

The electronic control board is a major component that orchestrates the washer's functions. These instructions explain h…

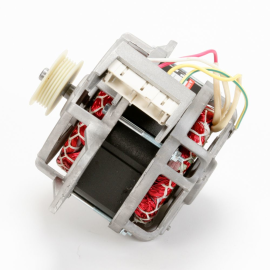

How to replace the drive motor in a top-load washer

The drive motor creates the rotation that turns the spin basket and agitator. If those components won't budge, replace t…

Effective articles & videos to help repair your washers

Use the advice and tips in these articles and videos to get the most out of your washer.

Find tips for using your washing machine efficiently to save energy and help reduce utility bills.…

Learn about all the convenient features on our Sears PartsDirect website that make your parts purchases easier.…

Get answers to frequently asked questions about Sears and Sears PartsDirect.…