Refrigerator: What routine maintenance does my refrigerator need?

Routine maintenance helps your refrigerator run more smoothly, so it uses less energy. Clean the condenser coils regularly to help the sealed system cool down the refrigerator efficiently. The compressor won't run as frequently if you keep those condenser coils clean. Adjust the refrigerator door to prevent air leaks into the refrigerator and freezer compartments. Air leaks cause frost buildup on the evaporator, which interrupts airflow and causes cooling problems.

Routine maintenance can also help prevent odor problems. Clean the inside of the refrigerator so spills don't build up and cause smells. Adding an air filter also can reduce refrigerator smells. Clean the drain pan under the refrigerator regularly because that pan can attract bugs or residue that causes odors.

THESE REPAIRS MAY HELP SOLVE YOUR REFRIGERATOR PROBLEM

Clean the refrigerator condenser coils

Dust-covered refrigerator coils can prevent the refrigerator and freezer from running efficiently and cooling properly. Follow the instructions in your owner's manual for cleaning the condenser coils. Unplug the refrigerator before accessing and cleaning the coils. On most refrigerators, the coils are behind the bottom front grill. Clean the condenser coils with a coil brush.

Clean the refrigerator condenser coils

How to clean refrigerator condenser coils

Does the ice cream in your freezer seem too soft or the beverages in your refrigerator not cold enough? It could be the condenser coils need to be cleaned. This DIY repair guide shows how to clean the refrigerator condenser coils in 4 easy steps.

Adjust the freezer or refrigerator door

The refrigerator or freezer doors swing on hinges that can be damaged or bent. Over time, the doors may begin to sag, allowing warm moist air into the refrigerator or freezer door that creates excessive frost that can eventually cause the drain tube to freeze. This refrigerator repair involves adjusting or repairing the hinges so that the doors work properly and stay aligned.

Adjust the freezer or refrigerator door

Clean the refrigerator drain pan

As part of the refrigerator's defrost cycle, the fridge drain pan collects condensate water that melts from the evaporator fins, collects in the evaporator drip tray below the evaporator and then flows through the defrost drain tube to the drain pan in the machine compartment next to the compressor. The drain pan can sometimes form mildew or collect insects. This repair involves accessing and cleaning the drain pan.

Clean the refrigerator drain pan

Most common symptoms to help you fix your refrigerators

Choose a symptom to see related refrigerator repairs.

Main causes: control board or cold control failure, broken compressor start relay, compressor motor failure, defrost tim…

Main causes: jammed ice cubes, broken ice maker assembly, dirty water filter, kinked water line, bad water valve, freeze…

Main causes: damaged door seal, faulty defrost sensor or bi-metal thermostat, broken defrost heater, bad defrost timer o…

Things to do: clean condenser coils, replace the water filter, clean the interior, adjust doors to prevent air leaks, cl…

Main causes: blocked air vents, compressor problems, condenser or evaporator fan not working, control system failure, se…

Main causes: water valve leaking, frozen or broken defrost drain tube, overflowing drain pan, cracked water system tubin…

Main causes: leaky door gasket, defrost system failure, evaporator fan not running, dirty condenser coils, condenser fan…

Main causes: blocked vents, defrost system problems, evaporator fan failure, dirty condenser coils, bad sensors, condens…

Most common repair guides to help fix your refrigerators

These step-by-step repair guides will help you safely fix what’s broken on your refrigerator.

How to replace a refrigerator temperature control board

If the temperature in your refrigerator doesn't match the temperature you set, the problem could be the temperature cont…

How to clean refrigerator condenser coils

Help your refrigerator run more efficiently by cleaning the condenser coils. It's easy and takes just a few minutes.…

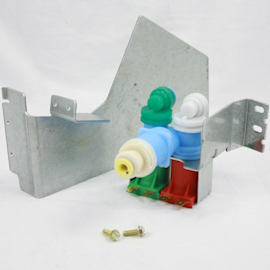

How to replace a refrigerator water valve

Replace the water valve that feeds water to the ice maker and water dispenser if it no longer controls the flow of water…

Effective articles & videos to help repair your refrigerators

Use the advice and tips in these articles and videos to get the most out of your refrigerator.

See how to install the water filter on your GE refrigerator, no matter the filter type or refrigerator style.…

No matter what style Maytag refrigerator you have, we can walk you through replacing the water filter.…

Get tips and advice on replacing the water filter in your LG refrigerator.…